Share this:

Welcome to the UNIDO Montreal Protocol Newsletter

We are experiencing increasingly severe heatwaves driven largely by a fossil-fuel charged, human-induced climate crisis. In June 2024, the United Nations Secretary-General António Guterres has called for an urgent and concerted effort towards addressing the challenge. The World Meteorological Organization (WMO) declared that 2024 was the warmest year on record.

With a growing demand for cooling equipment, the global energy consumption for cooling is projected to increase by five times and the number of cooling appliances quadruples to 14 billion. Under such circumstances, the importance of sustainable cooling cannot be ignored.

We spoke to Dr. Yosr Allouche, Director-General, International Institute of Refrigeration (IIR) based in Paris. A world-renowned academic and a refrigeration scientist with over 15 years of experience in addressing refrigeration challenges and promoting sustainable refrigeration practices. She also is the first woman to lead IIR as the DG.

When we discuss sustainable cooling and energy efficiency, we cannot ignore the work of UNIDO in the areas of circular economy and resource efficiency. In this newsletter, we profile Smail Alhilali, Director of UNIDO’s Division of Circular Economy and Chemicals Management in the ‘Ask UNIDO’ section. He shares insights from his life and speaks on the need to focus on integration and scaling up climate action efforts.

UNIDO’s Montreal Protocol Unit works tirelessly to promote climate friendly policies. This includes building key skills of technicians in the refrigeration and air conditioning sectors. Our feature story from Uganda highlights the decentralized approach to the training centres in the country and profiles Asuru Antazia, a woman technician who is applying new skills in her profession.

Test your knowledge in the quiz section and have a look at our notice board. It features some of our main activities—UNIDO’s achievements under the Montreal Protocol for 2024. Other reports include Ecuador launching a ‘Best Practices’ guide and UNIDO attending the Montreal Protocol Europe and Central Asia (ECA) network meeting in Belgrade.

We invite our readers to inform us of topics that you would like to be covered in our forthcoming newsletters or if you have specific questions. Please like and follow our social media channels—LinkedIn and Facebook for latest updates.

Happy Reading.

Your MPU Team

ASK UNIDO

Smail Alhilali

READ MORE

INTERVIEW

Dr. Yosr Allouche

READ MORE

FEATURE ARTICLE

Jayaraj Manepalli

READ MORE

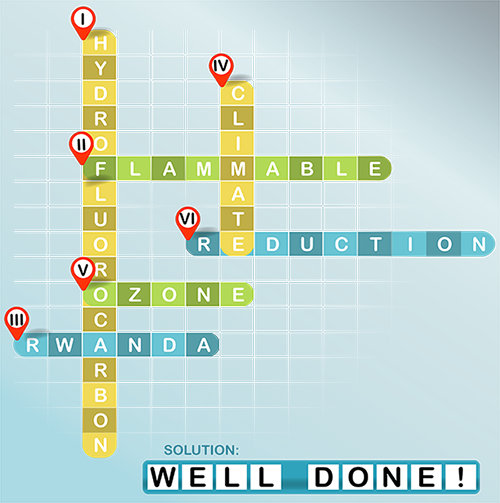

QUIZ - Did you know?

Test your knowledge!

Which grouping of states are the largest emitters of CO₂ in 2023 and how much did they emit?

What major measures of deployment can greatly reduce emission potential?

If only current Nationally Determined Contributors (NDCs) are implemented and no further ambition is shown in the new pledges, what is the scenario?

What is the main driver of the triple planetary crisis of climate change, pollution and biodiversity loss?

NOTICE BOARD

Spotlight

UNIDO’s CLIMATE ACTION: In 2024, UNIDO’s Montreal Protocol projects helped avoid 82 million metric tonnes of CO₂ emissions—equal to taking 19.2 million cars off the road for a year!

Social Media

Ecuador launches Best Practices' Guide on handling equipment with Hydrocarbon refrigerants; Over 250 technicians attend trainings

Events

UNIDO attends the Montreal Protocol Europe and Central Asia (ECA) network meeting organized by the UN Environment Programme (UNEP) in Belgrade.

ASK UNIDO

You Ask, We Answer!

Smail Alhilali, Director of Circular Economy and Chemicals Management Division at UNIDO says that integrating and scaling up global climate action efforts hold the key to protecting our planet

Integrating and scaling up global climate action efforts hold the key to protecting our planet

Smail Alhilali serves as Director, Circular Economy and Chemicals Management Division at UNIDO in Vienna, Austria. He leads the implementation of UNIDO’s programmes and projects on circular economy, resource efficiency and chemicals management contributing to achieve inclusive and sustainable industrial development.

Before joining UNIDO, he was the Director of Morocco National Cleaner Production Centre and served in different positions within the National Centre for Nuclear Energy, Sciences and Technologies in Morocco. Smail holds Master’s degrees in Mechanical Engineering from École Mohammadia d’Ingénieurs, in Rabat, Morocco and in Nuclear Safety Engineering from L’Institut national des sciences et techniques nucléaires (INSTN) in Saclay, France.

In this issue, Smail speaks on the need to focus on integration and scaling up climate action efforts so that there is a visible impact in saving our natural resources and protecting our planet.

Hello Smail. Thank you for your willingness to share your views with us. Could you please give us a little background of your childhood and professional journey?

Thank you for this. I grew up in a city called Tiznit in Morocco. I come from a business family and my father was a businessman. My parents were always supportive of my educational pursuits. After my schooling, I studied Mechanical Engineering in Rabat. I continued my studies in France and obtained a degree in Nuclear Safety engineering.

I returned to Morocco and was a part of the industrial safety team at Morocco’s National Centre for Nuclear Energy, Sciences and Technologies. I served in different positions and was responsible for laying down the safety protocols for the plant. My work took me to the mineral extractive industry, especially phosphates. Morocco holds the world’s largest phosphate reserves at 50 billion metric tons, accounting for over 67 percent of total global phosphate reserves. Today, it is the second largest producer of phosphate in the world. I also contributed to work with the national railways, where the technology was used to detect the flaws in the rail lines and address them. I was also the director of Morocco National Cleaner Production Centre and served in different positions.

I vividly remember my first visit to the Vienna International Centre (United Nations, Vienna) in 1995 to participate in a technical workshop. I was impressed after seeing merits of the multilateralism which I witnessed first-hand during that trip. A few years later, I ended up joining UNIDO.

At UNIDO, you lead many initiatives, especially those related to circular economy, responsible minerals and mining, and other projects that offer alternate technologies and substitutes that minimize the impact of industries on the environment. Could you give us a brief overview and what could be done to improve our work?

Yes. I had the privilege to lead some of UNIDO’s initiatives and projects like those on Materials and Chemicals Management, Industrial Pollution Mitigation, Emerging Compliance Regimes, resource efficient and cleaner production, Global Eco-industrial Park Programme, among others.

Our work also deals with the electronic waste, plastics and supply chains. As a United Nations agency, UNIDO also works in the area of critical minerals, just transition, energy and digital transitions, among others. All the work we do should be a responsible voice of the global south.

What I find is that there is a greater need to focus on integration and scaling up efforts. We should avoid working in silos and approach in a pragmatic manner. This could mean working to focus on priority projects, companies and working together with other UN agencies. For example, when we talk about decarbonization, we should adopt a ‘client approach’. In my view, this will produce more tangible results and outcomes.

All the economies are endowed with natural resources. We should aim to customize our programmes as per the local availability of resources and the priorities of the country. In other words, there is no ‘one size fits all’ approach but the programmes and projects are tailor made keeping in the priorities of the country, industry and the international regulations.

UNIDO delegation, led by Deputy to the Director General Ciyong Zou at the COP 19 in Cali, Columbia. Smail is fourth from left.

One of the roles you play at UNIDO is of being the Organization’s focal point for numerous multilateral agreements like the Stockholm Convention, Minamata and the Instrument to End Plastic Pollution. Could you explain how UNIDO’s work is in line with all these treaties?

UNIDO, as the specialized agency of the UN specifically focusing on Industrial development, has a great responsibility towards the planet and the people. All these multilateral agreements were agreed upon after rigorous scientific evidence, deliberations and the urgency of the issues pertaining to our planet.

Inclusive and Sustainable Industrial Development (ISID) is not only about economic development but also job creation. We cannot separate the human aspects of development from the overall industrialization. Due to the scarcity of our planetary resources, there is a growing emphasis on adopting circular economy principles in different conditions, including industrialization.

As mentioned earlier on the uniqueness of the economies and their natural resources, our programmes should be tailor-made keeping in the priorities of the country, industry and the international regulations. For example, we could integrate the usage of bamboo or timber and wood in the bigger programmes and supply chains, rather than focusing only on cement and concrete.

You had recently attended the COP19 (Biodiversity Summit) that took place in Cali, Columbia. Could you throw light on the current initiatives and developments?

The COP 19 Biodiversity summit that took place in Cali, Colombia, in November 2024 was a great experience. This COP’s highlight was the emphasis on living in harmony with nature. A historic decision was made to create a permanent body within the Convention on Biological Diversity to represent Indigenous Peoples and local communities in future biodiversity negotiations. This is a positive step that ensures their voices and traditional knowledge are integrated into global conservation strategies.

The countries at the COP 19 also agreed on a new benefit-sharing mechanism for genetic resources, known as the “Cali fund,” after extensive discussions. However, there was no final consensus on the biodiversity financing. Despite the challenges, the progress is being made even though much more needs to be done.

UNIDO delegation, led by Deputy to the Director General, Ciyong Zou had numerous consultations with various partners. The delegation learned about Santiago de Cali city’s vision and priorities in biodiversity in a meeting with the city’s Mayor and host of COP16, Álvaro Alejandro Eder.

The Global Environment Facility (GEF)’s latest cycle of funding for various projects also shows emphasis on the biodiversity related projects—as over half of the US$ 5 billion project funding was on projects related to biodiversity.

Smail at the Partnership for Action on Green Economy (PAGE) Summer School held at UNIDO HQ in Vienna where the participants learnt on the crucial role of circular economy in driving systemic transformation and the policies and practices needed to drive it.

Some of your work in the Stockholm Convention pertains to numerous chemicals. The Montreal Protocol also seeks to phase down harmful chemicals—especially those used primarily in the air conditioning and refrigeration, foam and solvents sector. There has been a growing concern on per- and polyfluoroalkyl substances (PFAS), also known as forever chamicals. How can you see the intersection of Montreal Protocol with other environmental treaties?

The Stockholm Convention, Minamata Convention and Montreal Protocol often address overlapping issues due to their shared goals of protecting people and the planet from some of the pressing environmental challenges we face.

While the Stockholm Convention targets persistent organic pollutants (POPs) that remain in the environment for long periods and can cause adverse health effects, Minamata Convention seeks to reduce the usage and emissions of mercury and Montreal Protocol deals with a specific set of chemicals causing damage to the Ozone layer and also causing global warming. The recent studies showing the harmful effects of Per and polyfluoroalkyl substances (PFAS), also known as forever chemicals and their impact on humans and ecosystem only highlight the necessity of addressing the issues not in silos but in a holistic manner.

The success of the Montreal Protocol and the combined global efforts in addressing the challenges should be a role model for the global efforts to address the triple planetary crises of climate change, pollution and loss of biodiversity. All of these treaties address one or more of the Sustainable Development Goal (SDGs). Sustainable industrialization can address all these issues simultaneously by helping the countries to leapfrog and adopt environmentally friendly measures and technologies.

How can UNIDO leverage its advantage owing to its work with the governments and the industry—to strengthen the drive further towards adopting circular economy principles, leading to efficient resource management and climate action?

UNIDO is the specialized agency of the United Nations with a unique mandate to promote, dynamize and accelerate industrial development. UNIDO’s mandate is reflected primarily in Sustainable Development Goal (SDG) 9: “Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation”, but our activities contribute to all the SDGs.

We seek to address the global challenges through sustainable industrial development—by driving industrial policies, technical cooperation and investment promotion activities that lead to industrial development and economic transformation but also result in the creation of new, decent jobs.

With its experience from various member states and the best practices, UNIDO can leverage its expertise to build a greater focus on integrating and scaling up efforts. We could focus on priority projects, private sector and investors and collaborate with other multilateral agencies.

By supporting the development and deployment of new technologies, and the application of new ways of thinking, we seek to address the triple planetary crises.

INTERVIEW

Interview

Dr. Yosr Allouche, Director-General of the International Institute of Refrigeration (IIR) believes that looking at the refrigeration challenge holistically is the best solution to achieve sustainability.

Looking at the refrigeration challenge holistically is the best solution to achieve sustainability

In this issue, we interviewed Dr. Yosr Allouche who was elected as the new Director-General of the International Institute of Refrigeration (IIR), an inter-governmental organization which was founded in 1908 and is based in Paris. She took up the new role in October 2024 also becoming the first female DG of IIR, succeeding Didier Coulomb. Dr. Allouche is a Norwegian-Tunisian refrigeration scientist and a world-renowned academic. She has over 15 years of experience in addressing refrigeration challenges and promoting sustainable refrigeration practices.

In this exclusive interview, Dr. Allouche spoke to UNIDO Montreal Protocol Unit’s Elena Miceva and Jayaraj Manepalli about her journey, the cooling challenges the industry faces, the need for research and industry application, importance of multilateral agencies like UNIDO, the necessity of accelerating sustainable cooling technologies, among others.

Congratulations Dr. Allouche on your new role. Coming from an academic environment to an intergovernmental agency might have been a big shift career-wise. Could you give us a background on your life and professional journey?

Thank you! It has been an intense and enriching transition period taking over from Didier Coulomb. I come from an academic background and am a refrigeration scientist. My family was supportive of my pursuits, and I always looked for challenges and to never stop learning.

I studied mechanical engineering and completed my doctoral studies as an Erasmus student from the University of Porto in Portugal. My journey with refrigeration started while reviewing PhD proposals. I came across one on solar-driven ejector cooling systems, which I found fascinating. The idea of achieving cooling through solar energy was quite interesting and led me to explore this area. That is how I entered the world of refrigeration. After finishing my PhD in 2016, I went to do research at the Energy Process Technologies department at the Norwegian University of Science and Technology (NTNU). My work mainly focused on CO2 refrigeration systems with integrated PCM energy storage, and I learned a lot from Professor Armin Hafner. I joined NTNU as a postdoc, continued as a refrigeration researcher and then as an associate professor in refrigeration.

Later, I moved to France and had the opportunity to be associated with the work of the IIR. I served as the Head of Projects for three years when the Norwegian delegation proposed me as a candidate for the Director-General of IIR. I was subsequently elected by the majority of the IIR member countries.

Having spent over years in research and academia, I now look at the issues from a different perspective. My academic background and research complement my current work. I am still a researcher, but I now also look at the real-world implementation part—identify the gaps and how to integrate the volumes of research data we have into policy making and actual implementation.

Can you explain to our readers the work of the International Institute of Refrigeration—its priorities and the direction it has been taking in the last few years.

IIR is a unique Inter Governmental Organization 100% dedicated to refrigeration and heat pump science. The IIR provides independent, research-backed third-party advice in these fields. It has 58 member states. IIR was a visionary organization in the sense that it was promoting the use of natural refrigerants since its early days.

Owing to its long history, the IIR has a wealth of knowledge–drawn from over 400 of the world’s top scientists and experts–which we are happy to share this knowledge with industry and all other stakeholders. This includes knowledge in areas like cryogenics and liquified gases, thermodynamics, refrigeration equipment and systems, biology and food technology, refrigerated storage and transport, air conditioning, heat pumps and energy recovery, all applying non-ozone depleting and low global warming refrigerants. The IIR recommends technology based on scientific evidence. Our technology briefs are well known in the industry. We seek to bridge the gaps between research and industry on the one hand and between research and policy making on the other.

The IIR engages in extensive research and publishes numerous technical briefs, policy briefs, webinars, newsletters, and co-owns with Elsevier, the International Journal of Refrigeration, the unique scientific journal in the refrigeration field. IIR also organizes many conferences, especially the International Congress of Refrigeration, Gustav Lorentzen Conference on Natural Refrigerants, Conference on Sustainability and the Cold Chains, Conference on Compressors and Refrigerants, Cryogenics, among others. Innovation remains the key area of our work as we work with all stakeholders.

I want to make our knowledge products available to raise awareness on the importance of new and climate-friendly technologies. IIR also wantsto focus on projects supporting education and knowledge transfer, especially to the countries in the global south. Because the needs in the south are different than those in the north. For example, the focus on the global north where research around refrigeration and heat pumps is well developed is to be part of a unique international network of pioneering researchers and experts in the refrigeration sector. The needs in the Countries of the global south are different. It is more on how we can enable implementation and create infrastructure, with examples from other countries, support them with capacity building programmes. We need to make this crucial knowledge transfer which can be adapted to specific conditions and needs of a country. I envisage the IIR to be the first go-to advisor for governments when discussing technologies to invest in and implement in the local refrigeration industry.

I want to make our knowledge products available to raise awareness on the importance of new and climate-friendly technologies. IIR also wantsto focus on projects supporting education and knowledge transfer, especially to the countries in the global south. Because the needs in the south are different than those in the north. For example, the focus on the global north where research around refrigeration and heat pumps is well developed is to be part of a unique international network of pioneering researchers and experts in the refrigeration sector. The needs in the Countries of the global south are different. It is more on how we can enable implementation and create infrastructure, with examples from other countries, support them with capacity building programmes. We need to make this crucial knowledge transfer which can be adapted to specific conditions and needs of a country. I envisage the IIR to be the first go-to advisor for governments when discussing technologies to invest in and implement in the local refrigeration industry.

What are the challenges we face regarding refrigeration? What are some potential measures we could adopt to address these challenges?

Refrigeration plays a crucial role in our daily life. Currently, 12% of the world’s food production is lost due to inadequate cold chains. Food that if saved, could nourish over 950 million people who go hungry each day. Each year, 1.5 million people year lose their lives due to vaccine-preventable diseases, while over 20% of pharmaceutical products are damaged due to broken cold-chains.

Increasing temperatures also influence labour productivity—leading to a reduction in productivity by as much as 12% in South Asia and West Africa by 2050, resulting in up to 6% GDP loss annually. Increased heat stress can reduce global GDP by $2.4 trillion in 2030. Access to high quality, safe food, human comfort, and temperature-sensitive health products are fundamental rights that must be protected. Strengthening refrigeration and cold chain infrastructure is essential to addressing these challenges, hence the urgent need to find cooling solutions that are sustainable.

However, Refrigeration is energy-intensive and consumes approximately 20% of global electricity and this demand is projected to double by 2050 without decisive policy action. In parallel, millions of electrically driven heat pumps are needed to substitute fossil fuel heating. To keep the 1.5-degree scenario within reach, it is important to address the challenge.

I believe there are three main goals we all need to strive for in this sector.

- Promote low-global warming potential (GWP) refrigerants

- Focus on energy efficiency

- Reduce the cooling demand

Before even looking at the refrigerant selection and energy efficiency, it is important to deep dive into how we can reduce the cooling demand. There are numerous passive opportunities available to reduce this cooling demand. All tools and knowledge to support the deployment of new energy-efficient equipment and the selection of the appropriate refrigerant already exist.

But we need to be careful to look at the issue holistically, because “low-GWP” does not mean it is energy efficient, and vice versa. Energy efficiency and type of refrigerant are linked. For instance, if you select a low-GWP refrigerant and thus reduce the direct emissions from refrigerant leakage, but your system is not energy efficient and leads to increased indirect emissions, it does not make sense. It is important to consider all these factors at the same time. We need to find a compromise between these three goals to find the best solution to achieve sustainability. This also has great potential to mitigate climate change.

What do you think of women in cooling sector? As the first woman Director-General of the IIR your voice especially matters in this crucial area.

The IIR has been around since 1908, always led by men. My election was primarily based on my credentials and the vision for IIR and the voting by the members. In this sense, it is a big achievement for women, and I am very happy to be elected. I also believe that we need more women in leadership in the refrigeration and air conditioning sector.

There is an increasing awareness on the cooling sector, and we are witnessing many women engineers and technicians entering the field. We also see a growing number of engineering students interested in the new career opportunities in the area. Numerous scholarship programmes for women to study refrigeration technology is a positive step which encourages women participation.

Women technicians, especially in smaller towns and villages in my view, can also effectively convey the messages and good practices on refrigeration and environmental protection. Even though the signs look promising, there is much more to do. We need to build a capable and skilled workforce of refrigeration technicians across many countries, training them to operate and maintain a system safely and efficiently.

At IIR, we are actively involved with the International Network of Women in Cooling (INWIC), looking at how to empower more women in the cooling sector. The IIR took the INWIC Presidency this year. We are also very active in CaRe (Careers in Refrigeration) where we talk to young people about the opportunities in the sector and how they can efficiently contribute to the transition of the sector.

At IIR, we are actively involved with the International Network of Women in Cooling (INWIC), looking at how to empower more women in the cooling sector. The IIR took the INWIC Presidency this year. We are also very active in CaRe (Careers in Refrigeration) where we talk to young people about the opportunities in the sector and how they can efficiently contribute to the transition of the sector.

The Multilateral Fund for the Implementation of the Montreal Protocol emphasizes the role of energy efficiency and sustainable cooling, as observed in the recent decisions of the Executive Committee. How can we address this challenge and offer sustainable solutions?

I think this is the right direction and we have seen numerous studies which highlighted the need for sustainable refrigeration technologies. Taking the example from the success of the Montreal Protocol which paved way for global efforts towards climate action, we need to involve all stakeholders and emphasize the urgency of adopting the right climate solutions.

The Call to Action on extreme heat by United Nations Secretary General stresses on the urgency of the problem. I believe we need to engage in more conversations with the stakeholders, with the technology providers, energy companies, refrigeration equipment manufacturers and others. When we look at the potential to reduce food wastage using energy-efficient technologies, we understand that adding pre-cooling at farm stage is important to address food security challenges.

We need to focus on a holistic approach addressing multiple challenges. Opting for space cooling, building with climate friendly material and technologies, district cooling and passive cooling measures in our new constructions and urban planning–these measures help us to look at the challenges holistically. Technologies like the Variable Refrigerant Flow (VRF) air conditioning systems which can lead to expanded capacity and energy efficiency improvements—with both heating and cooling options– could be considered. VRF is an advanced system that provides precise control over the amount of refrigerant flowing to multiple indoor units. This enables the choice of individualized heating and cooling in different zones of a building. Of course, policy makers need to take informed policy decisions based on scientific evidence.

How can UNIDO and IIR work together and capitalize on their strengths to address the cooling challenge and offer solutions?

UNIDO has earlier worked with IIR and published a few best practices in various aspects of refrigeration and cooling. I believe it is important to continue and deepen the cooperation. As a specialized UN agency tasked with industrial development, it is important that we ensure that industrialization is sustainable and addresses the climate challenges. It is important to incorporate more evidence-based policy and latest research in the policies and programmes UNIDO formulates and designs because these actions shape our future.

Our work impacts policy making. It is important to work closely with national ozone officers, develop national capacity building—be it by way of training the refrigeration technicians and officers, policy makers or the enforcement agencies or strengthening institutional capacity—every stakeholder’s role is important to address the triple planetary crises and to reach the SDGs. Integrating and scaling up global climate action efforts hold the key to protecting our planet. We look forward to strengthening our cooperation and diffuse the knowledge and best practices at a field level.

FEATURE ARTICLE

Feature Article

Jayaraj Manepalli, Communications Expert at UNIDO writes on how UNIDO’s project supported Asuru Antazia’s dream of acquiring necessary skills to become a refrigeration technician in Uganda.

Skills for saving lives: delivering climate solutions while protecting the planet

When Asuru Antazia heard about the training programme for refrigeration and air conditioning technicians being offered at the Amelo Technical Institute in the neighbouring Adjumani district, she was excited and readily signed up.

Hailing from Obongi district in Northern part of Uganda, Asuru was inspired by engineers and their work since childhood. Constantly motivated by her mother who encouraged her to never give up on her dreams, Asuru ended up pursuing refrigeration engineering course at the Uganda Technical College, Elgon.

“Even though the course was rigorous, the opportunity for practical work was limited. So, when I came to know about the five-day training offered by United Nations Industrial Development Organization (UNIDO), I was keen on learning the international best practices in cooling,” she says.

“Even though the course was rigorous, the opportunity for practical work was limited. So, when I came to know about the five-day training offered by United Nations Industrial Development Organization (UNIDO), I was keen on learning the international best practices in cooling,” she says.

The growing cooling challenge

With an estimated 3.6 billion cooling appliances in use today globally, the demand is only increasing – expected to reach 9.5 billion units by 2050. Providing cooling for all who will need it in a warming world – and not just to those who can afford it – could require 14 billion cooling appliances by 2050.

In Uganda by 2030, the number of domestic refrigerators in use will increase to 660,000 units and room air conditioners to 230,000 units. The annual sales are expected to reach 70,000 units of refrigerators and 25,000 units of air conditioners by 2030, as per UNEP-U4E 2020 study. Added to this is the usage of industrial refrigerators and air conditioners, which adds up to a much higher number. To keep up with this rapidly growing demand, there is a great need of suitable and skilled technicians.

UNIDO Montreal Protocol

UNIDO’s projects lay great emphasis on imparting training and skills to technicians. The use of environment friendly refrigerant gases in the cooling equipment, instead of those substances which cause ozone depletion and global warming, forms an integral part of the work under Montreal Protocol. UNIDO helps Member States in devising policies in line with the goals, objectives and timelines of the Montreal Protocol.

The equipment supplied to the training schools enabled ‘hands on’ experience to the trainees, leading to national capacity building and job creation opportunities. In Uganda, the main traininginstitute with advanced equipment is based in the capital,Kampala. “Technicians from the rest of the country often spend many hours to travel to the capital and with no means to cover the costs,” says Rodrigo Serpa, UNIDO’s Project Manager. This had become a major challenge, especially to technicians scattered in other cities and faraway places.

The equipment supplied to the training schools enabled ‘hands on’ experience to the trainees, leading to national capacity building and job creation opportunities. In Uganda, the main traininginstitute with advanced equipment is based in the capital,Kampala. “Technicians from the rest of the country often spend many hours to travel to the capital and with no means to cover the costs,” says Rodrigo Serpa, UNIDO’s Project Manager. This had become a major challenge, especially to technicians scattered in other cities and faraway places.

Trainings: Decentralized Approach

“We then identified six strategic locations which could serve as potential training centres. This decentralized approach will enable skills to be imparted to a maximum number of technicians,” Serpa added.

“So far, we have trained over 800 refrigeration technicians in Uganda, with UNIDO’s support. Refrigeration is a very unique profession, encompassing scientific knowledge and technical skills, giving practitioners the skills to attract employment,” said Paulo Odu, Project Coordinator.

All th e six training centres established so far are functioning well, showing their sustainability. Two centres-in Amuria district and in Adjumani became operational in 2023. This isnot only helping the technicians from Uganda but also attracting interest from bordering regions of Congo and South Sudan, explained Paulo.

e six training centres established so far are functioning well, showing their sustainability. Two centres-in Amuria district and in Adjumani became operational in 2023. This isnot only helping the technicians from Uganda but also attracting interest from bordering regions of Congo and South Sudan, explained Paulo.

Buoyed by success of the training activities, more such centers are planned across the country. “The best performing students are chosen to be trainers to the future batches. This way, the best practices in the industry are taught all across Uganda,” Rodrigo said.

Skills for saving lives: delivering climate solutions and -protecting the planet.

The five-day training in Adjumani put Asuru in a unique situation owing to her prior experience. Before becoming a refrigeration technician, Asuru worked as a nurse in the district. Having handled vaccines and medicines, especially during the critical times such as the Covid-19 pandemic, Asuru understands that proper cooling facilities can be a matter of saving lives. According to a report by WHO, each year, 1.5 million people lose their lives due to vaccine-preventable diseases and over 20% of pharmaceutical products are damaged due to broken cold-chain facilities.

“My responsibilities with the local government’s department of health include maintaining refrigerators for storing life-saving vaccines and medicines at the 17 health centres across the Obungi district. It involves touring the district to monitor and evaluate the facilities’ functionality and sometimes, even installations,” she says. The dual benefit of my work – that of using environment-friendly cooling technologies as well as using that technology to preserve vaccines and medicines which help save people’s lives, keeps me constantly motivated, Asuru added.

Read this story on UNIDO website: https://www.unido.org/stories/skills-saving-lives-delivering-climate-solutions-while-protecting-planet

CONTACT US

Subscribe to our newsletter

Sign up to receive a quarterly email with updates and new content!

Disclaimer

The information presented in this newsletter does not necessarily reflect the views of UNIDO. Links to external websites are included solely to provide additional information and do not imply any official endorsement of the opinions, ideas, data, or products presented.

© 2024 UNIDO Montreal Protocol