Share this:

Welcome to the UNIDO Montreal Protocol Newsletter

Welcome to the latest issue of our newsletter. As summer approaches the northern hemisphere, the utilization of the air conditioning and cooling equipment becomes more widespread and crucial than ever. This year, the northern hemisphere has been experiencing some of the hottest days ever recorded, reminding us of the need for urgent Climate Action.

This issue delves into the work done by UNIDOs Montreal Protocol Division, especially in the field of Refrigeration and Air Conditioning (RAC). In the Ask UNIDO section, former Director of Circular Economy and Environment Protection (CEP) division, Stephan Sicars explains his work, the future trends in the field of environmental protection and shares his insights gained from his wide experience.

In the interview section, we speak with Claudia Paratori Cortés, Coordinator of the National Ozone Unit of Chile. She explains the recent establishment of the refrigerant recovery centres in the country, how these actions align with the pathway of the Kigali Amendment to the Montreal Protocol and the national climate goals of Chile.

Our feature story explains how the refrigerant recovery and reclamation centres play a major role in addressing climate challenges—by paving way towards a circular economy in refrigerants—leading to skill development, employment generation and enabling a clean transition.

Test your knowledge in the quiz section and have a look at our notice board. It features our main events—The Kigali Implementation Plans workshop that brought together National Ozone Officers and delegates from over 50 countries. Other reports include the launch of a scholarship programme for young women in Nigeria to pursue a career in the Refrigeration and Air Conditioning (RAC) sector, where they are underrepresented.

If you have any questions, please write to us and we will try to answer in our forthcoming issues. Please like and follow our social media channels UNIDO Environment on LinkedIn and Facebook.

Happy Reading,

Your MPD Team

ASK UNIDO

Stephan Sicars

INTERVIEW

Claudia Paratori Cortés

Explains the story of establishing the refrigerant recovery and reclaim (RRR) centre's network in Chile.

FEATURE ARTICLE

Jayaraj Manepalli

Writes on how promoting circularity of refrigerant gases paves way for climate-friendly cooling solutions.

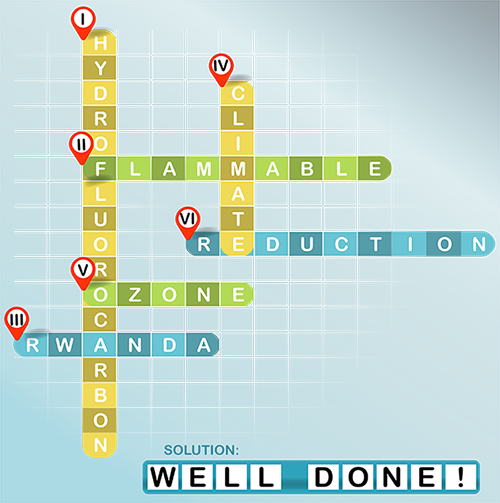

QUIZ - Did you know?

Test your knowledge!

What was one of the major findings of the World Meteorological Organization’s State of the Global Climate Report 2022 on earth’s temperature?

What are known as the ‘big three’ greenhouse gases (GHGs)?

How long do the greenhouse gases stay in the atmosphere?

How does the vulnerability to extreme weather conditions affect people compared to those living in resilient areas?

NOTICE BOARD

Spotlight

The three-day Kigali Implementation Plans workshop, organized by UNIDO’s Montreal Protocol Division was held from 14th to 16th June in Vienna. It attracted National Ozone Officers, International Experts and Specialists from over 50 countries.

Social Media

UNIDO submitted the Kigali Implementation Plan (KIP) on behalf of Cameroon at the 92nd meeting of the Executive Committee of the Multilateral Fund. This was the first KIP to get approval.

Events

UNIDO facilitates the growth of female experts and policymakers who vigorously advocate for women’s inclusion in the Refrigeration and Air Conditioning sector.

At least sixty female engineering students in Nigeria will be awarded scholarships over the next two years.

ASK UNIDO

You Ask, We Answer!

Interview with Stephan Sicars, who served as Director, Circular Economy and Environmental Protection (CEP) Division till June 2023 on how the Montreal Protocol continues to address key environmental challenges.

From having contributed as the lead author of the reports of the Intergovernmental Panel on Climate Change (IPCC), which was awarded the Nobel Peace Prize in 2007, to playing a key role at the Multilateral Fund (MLF) Secretariat of the Montreal Protocol, Stephan Sicars has an impressive career record in the field of climate action. In this issue, we ask Stephan on his work with UNIDO’s Montreal Protocol division, the current trends related to environment and his insights.

Could you give us a brief background of your work and the role in UNIDO’s Montreal Protocol Division?

After completion of my studies, I worked for and later managed, the Research Centre for Refrigeration and Heat Pumps in Germany. Later, I set up a consultancy, which specialized in undertaking research for international industries, NGOs and governments. Having experience of implementing projects in India and China, I provided policy advice on environment matters and served as a technical expert on several international panels.

I joined United Nations as Senior Programme Officer with the Multilateral Fund for the Implementation of the Montreal Protocol in 2004. I came to UNIDO in 2014 and became the Director of the Department of Environment in 2015. I focused the department’s work towards reducing emissions of greenhouse gases, minimizing industrial pollution and advancing circular economy. In addition, between 2020 and 2022, I oversaw UNIDO’s Energy portfolio. I was also responsible for managing climate action across all of UNIDO’s departments and advancing programmatic work with several strategic donors, including the Green Climate Fund.

With the challenges of global warming we face today and the global commitments made under the Paris Agreement, how does the Montreal Protocol Division of UNIDO play a role and what effect does it have on the future work?

UNIDO has always been at the forefront of climate action, especially under the Montreal Protocol. The progress observed in the recovery of ozone layer, as mentioned in the latest quadrennial report of the World Meteorological Organization (WMO), is a testament to the joint global climate actions under the Montreal Protocol. As one of only four implementing agencies of the Montreal Protocol, UNIDO actively works in the area of climate action.

The focus now is to keep our climate targets within the limits as prescribed in the Paris Agreement. Energy efficiency plays a crucial role in fighting the climate challenges. This will be a major theme in the coming years. With a warming world, growing population, increasing demand for energy and cooling, energy efficient devices will become an important part of modern life.

It is upon all the stakeholders to continue the good fight and keep the momentum of all the gains made in the last decades in climate action. This brings us to the need for coherent design of projects that harmonize the goals of the environment (climate) and energy.

What is MPD doing on the Circular Economy and Net Zero economy? Where is the greatest impact felt?

Circular economy is the next phase of climate action. If we observe the last two decades, the Montreal Protocol has conducted the largest sectoral training programmes globally and many such programmes placed due emphasis on the circular economy and sustainability.

Circular economy is an industrial economy that routes materials, parts and products back into use, repeatedly, to create more value and less waste. In this economy, the value retained for as long as possible, products designed to last longer, and the generation of waste minimized. Under UNIDO’s Montreal Protocol projects, we support stakeholders in developing circular economy strategies and policies, applying these directly within industries. We work directly with companies to transform their linear production models.

Factory conversion projects undertaken in particular in the RAC sector, place their emphasis on innovation and adopting new technologies. This ‘need for redesign’ provides us a great opportunity to design out the pollutants, in our case the ozone depleting substances. This also opens up the possibility to design for longevity, which is arguably the case for hydrocarbon conversions and incorporating a circular economy objective. At the same time, we frequently upgrade the “resource efficiency in production” whenever we undertake the industrial conversion projects.

Let us not forget that circular economy itself, through saving the energy associated with the production and transport of resources, is a very important step towards achieving net zero. The potential of circular economy to contribute to net zero is in some studies said to be 50% of the anthropogenic climate impact.

The global community, including the international organizations like UNIDO, have already laid the primary groundwork on renewable energy and climate protection. Historically, Montreal Protocol (MP) has worked a lot on this area over many years. Particularly, the RAC equipment and appliances are causing a very substantial part of the electricity consumption in many developing countries. Conversions – in particular towards hydrocarbons – increase the potential and decrease the cost to implement additional energy efficiency measures. Through the high aggregated electrical energy consumption of these systems, the impacts towards net zero achievable through these measures are remarkable.

How has the Kigali Amendment altered the landscape of the Montreal Protocol?

The Kigali Amendment aims to fight global warming by phasing down the usage of Hydrofluorocarbons (HFCs) which have a high global warming potential. The Kigali Implementation Plan provides a great opportunity for UNIDO to coordinate its work with other agencies and stakeholders, especially member states. The MP Community and MLF have to coordinate and streamline their efforts.

Usually, in most cases, the countries are isolated from latest happenings in the field of environment and climate change and may need time to design better policies and enable relevant legislation. Two decades ago, we had challenges to convince the countries on streamlining the custom regulations. However, with the situation of the Kigali Amendment, there is an increasing realization for streamlining the policies, especially when the challenges are global and needing our immediate attention and joint actions.

What do you think are the strengths of UNIDO as an implementing agency of the Montreal Protocol?

UNIDO holds excellent technical talent, which has been built over the years. The experiences from various projects from around the world, best practices and the lessons learnt, gives it a large amount of technical know-how. This helps UNIDO in undertaking and implementing various projects effectively and efficiently—from commissioning of factories to implementing large-scale projects.

Building on these strengths, UNIDO can optimize its technical cooperation projects and facilitate cooperation between various stakeholders. It should aim towards concrete, progressive and smart design of projects. UNIDO can maximize the case of low Global Warming Potential (GWP) substances, especially in the Refrigeration and Air Conditioning (RAC) and foam sectors. UNIDO always stood for finding innovative solutions and in this sense, I would call UNIDO a visionary. There is a huge capacity in UNIDO, which can be customized according to the priorities of the Organization to deliver high quality leadership owing to its technical strength and vast experience and expertise.

Looking back at the work you did, are there any milestones that make you satisfied or proud about?

When I look at the aggregate climate impact of activities where UNIDO Montreal Protocol operations supported governments and industry since I joined, which would be in the order beyond 500 million metric tons of annual CO2 emission reduction, it gives me a great sense of satisfaction.

The MP team of UNIDO has helped countries and industries to achieve their climate action goals. I was trusted and honoured to provide the overall leadership and management and to accompany in their work. I am also proud of the active role UNIDO plays now in the Montreal Protocol as an implementing agency.

Let me say here that I wish all those working tirelessly on the Montreal Protocol, whether in negotiations, assessments, issuance of regulation, or implementation. Whether working in national governments, industry, other entities, multilateral agencies like UNIDO, or in the Ozone or Fund Secretariats: The Montreal Protocol is considered the most successful treaty because of all of us, and I wish all of you continued enthusiasm, commitment and success to further strengthen the positive image of the Montreal Protocol through many more related success stories.

INTERVIEW

Interview with Claudia Paratori Cortés, Coordinator of the National Ozone Unit in Chile

Claudia Paratori Cortés, Coordinator of the National Ozone Unit (NOU) in Chile explains the story of establishing the refrigerant recovery and reclaim (RRR) centres network in Chile.

What are the main components of the HCFC phase-out management plan (HPMP) in Chile and how are these linked to the Kigali HFC Implementation Plan (KIP)? How do the refrigerant recovery and reclamation networks contribute to these objectives?

Chile is currently implementing the HPMP Stage II in the country. The focus is on the demonstration projects of industrial conversions in refrigeration and air conditioning (RAC) systems and establishing three refrigerant reclamation centres. These activities are complemented with training courses on good practices in refrigeration.

HPMP Stage III will reinforce these activities by implementing the Zero Leaks Programme, providing technical assistance to reclamation centres and certification of women technicians in the RAC sector.

We hope to present the Kigali Implementation Plan at the 95th Meeting of the Executive Committee of the Multilateral Fund (MLF). The HPMP and the KIP can be synergized through activities focused on replacing refrigerants with alternatives having lower global warming potential (GWP), such as natural refrigerants (CO2, NH3, hydrocarbons). Chile has made great progress in the implementation of CO2 trans-critical systems, which has proven to be a suitable technology for the country. It is also exploring hybrid systems with natural and new synthetic refrigerants.

A potential area of synergy between the two is the Zero Leaks Programme, which is perfect to integrate the HPMP and KIP, since it involves best practices in refrigerant management, reduction of leakages, energy efficiency and technicians’ certification. This programme will lay the foundation for conversion towards non-HFC and zero GWP alternatives. Additionally, refrigerant reclamation plays a crucial role in both programmes, ensuring the availability of reclaimed refrigerants for users undergoing conversion, in compliance with the Montreal Protocol.

Describe the journey of setting up the RRR centres network in Chile. What were the key drivers of this process? What kind of challenges did you face and how did you address them?

The process of establishing an RRR network was first considered in Chile under the Refrigerant Management Plan (RMP), but it was not feasible at that time due to existing market conditions. However, under the HPMP Stage I, programme design for reclamation was developed, providing the technical guidelines and business models. Regener Chile was selected as the pilot agency for the first refrigerant reclamation centre. The visionary approach of Regener’s Manager, José Luis Rojas, who sought to incorporate circular economy into all processes, was key for this initiative. Regener was included in a GEF project on the replacement of domestic refrigerators and now reclaims refrigerants and recycles/reuses cylinders and various components. As the National Ozone Unit (NOU), we were able to combine the reclamation project with the conversion projects under the MLF, so that the refrigerants banned under these projects had to be transferred to Regener.

In the HPMP Stage II, we found a more favourable market interested in reclaimed refrigerants. This could be because of the measures put in place to reduce HCFC imports, equivalent to a 65% reduction compared to the baseline. Now that less HCFCs are on the market, there is a greater interest in reclamation.

For the establishment of the three reclamation centres, the NOU held workshops to identify potential interested parties with an even geographical distribution as well as their equipment needs. Sustenta Chile (in the central part of Chile) and Sofrisur (southern part) and Comercial JJR, a subsidiary of Regener (northern part), were selected to participate in the initiative.

The main promoters of these centres, in addition to the NOU and Regener Chile, were the technicians and refrigerant distribution companies or refrigeration system installers/maintainers. The Ministry of Environment was also instrumental, in supporting recycling, circular economy and the implementation of the Extended Producer Responsibility (EPR) Law.

One challenge that remains is the assurance of the quality of the reclaimed refrigerants, since there is no laboratory in Chile that analyses refrigerants periodically, making each analysis done abroad, excessively expensive. Regener addressed this by requesting the analysis of composite samples (i.e. of several cylinders) and then, due to the high cost, with portable identifiers, which it maintains with periodic calibration and expert personnel. Under the HPMP Stage II, we are addressing this by providing portable analyser kits and Göetz Tubes.

What are the lessons learnt from your experience with the RRR centres’ network? What can National Ozone Officers in other countries learn from Chile’s experience in designing/strengthening their respective national networks?

The lessons learnt? There are many!

- Starting with the demand for reclaimed refrigerants, which is linked to the reduction or elimination of substances controlled by the Montreal Protocol, and with local regulations.

- Raising awareness on the benefits of a reclamation centre, especially demolishing the myths about reclaimed refrigerants and their quality, clarifying that their use is safe. In this line, also demolishing the myth that refrigerants are “consumables”, continued through the Zero Leaks Programme in HPMP Stage III.

- Conducting an initial study on the implementation of a reclamation centre, with its technical, technological and economic options, is crucial for discussion and calculation.

- Processes of open public calls, preceded by face-to-face or virtual dissemination workshops, and accompanied by the NOU was highly appreciated by the interested parties.

- Co-financing of the MLF for the implementation of the centres is a crucial initial impulse for facilitating the decision-making.

- Subsidies for the first amounts reclaimed made it easier for the centres to start operations and set reclamation goals for them, which prompted them to look for customers.

- The union between the government (Ministry of Environment) and the implementing agency (UNIDO) generated confidence among the interested parties were important to give guarantees.

- The training offered by the international expert generated confidence in the quality of equipment and facilitated the capacity building of the beneficiaries.

- Ongoing support of the NOU, including monitoring the reclamation amounts and involving them in relevant activities.

- The visits of the UNIDO counterparts to the reclamation centres generated trust and support for the work that is being carried out in each centre.

What are the next steps under the HPMP and KIP and what is your vision for the future?

The next steps in the HPMP Stage III and the KIP are to:

- Focus on strengthening the reclamation centres, mainly on the quality of the reclaimed refrigerants and on adequate equipment to meet market demand.

- Support the achievement of the reduction targets under the Montreal Protocol: for HCFCs reduction of 67.5% by 2025 and 100% by 2030, and for HFCs of freezing in 2024 and 10% by 2029.

- Monitoring the existing reclamation centres and evaluating the creation of new centres where needed.

- Address challenges related to the treatment or the reclamation of zeotropic mixtures (i.e. R-4xx series mixtures), analysing the technological options and/or strengthen training on their use and management.

- For the NOU’s future vision, it is essential to involve the reclamation centres in an integral cycle of good use and management of refrigerants, supported by regulations, training and technological conversions, and demolishing the erroneous myth that “refrigerants are consumables.”

FEATURE ARTICLE

Feature Article on Refrigerants' handling

Jayaraj Manepalli, Communications Expert at UNIDO writes on how promoting circularity of refrigerant gases paves way for climate-friendly cooling solutions.

There are an estimated 3.6 billion cooling appliances in use today across the world and this number is projected to increase to 9.5 billion by 2050, as per a United Nations Environment Programme (UNEP) report. Providing cooling for all who will need it in a warming world—and not just those who can afford it—could require 14 billion cooling appliances by 2050. Adopting energy efficiency measures in the refrigeration sector represent up to 80% of the CO2 emission mitigation potential when climate actions under the Kigali Amendment are implemented.

Right from their use in houses to the grocery stores, from food supply chain systems to automobiles, the refrigeration and cooling devices affect all aspects of modern life. Built into most of these devices is a fluorinated gas called the hydrochlorofluorocarbon (HCFC) or a hydrofluorocarbon (HFC) which is used as a refrigerant.

Valeria Arroyave Cardozo, Project Administrator from UNIDO’s Montreal Protocol Division at the inauguration of the refrigerant reclamation centre in Chile.

When these gases or chemicals are released into the atmosphere, normally at the end of the life cycle of the device, or due to a leakage, HCFCs cause great damage to the environment leading to the depletion of earth’s ozone layer. Both HCFCs and HFCs are extremely potent climate warmers. They absorb infrared radiation, trapping heat inside the atmosphere rather than allowing it to escape back into space, creating a greenhouse effect that warms the planet.

Globally, the installed base of HCFCs and HFCs is to the tune of 24 billion CO2 equivalent metric tons today, mostly in use as refrigerants according to a report by the Environmental Investigation Agency (EIA). The report also highlights that by correct handling of the refrigerants, their recovery and reclamation efforts can help avoid fluorocarbon emissions equivalent to 90 billion metric tons of CO2 by the end of this century.

Recovering these gases and reclaiming them is an important way to fight the climate challenge. The United Nations Industrial Development Organization (UNIDO) Montreal Protocol Division, in collaboration with various member states and partners has helped set up such centres, in numerous places. “A proper management of refrigerants paves way for a circular economy,” said Ole Nielsen, Chief at UNIDOs Montreal Protocol Division. Recently, such centres were inaugurated in Chile and Ecuador. So far, UNIDO assisted in setting up many such centres around the world as a part of our projects, Nielsen added.

“Reclamation is the process of converting the recovered refrigerant into a new product as per specifications either by distillation or electrostatic methods, as opposed recycling which removes only a certain level of impurities from the recovered gases,” said Ronald Viskil, an expert working in the field who was also associated with numerous UNIDO projects.

At the inauguration of the refrigerant reclamation centre at the Escuela Politécnica del Litoral (ESPOL) in Ecuador.

“The reclaimed product is as good as new, leading to cost reduction of the refrigerants, which otherwise would need expensive refills. However, a key to the success of the reclamation centers is having proper legislation and strict implementation in place and creating awareness on the advantages,” Viskil explained.

Often, refrigerants are handled in an unsafe manner leading to their release into the atmosphere. Sometimes banned and counterfeit refrigerants also enter the market, emphasizing the necessity of effective implementation of the law.

Many developing countries could ‘leapfrog’ from financial and technical support by international agencies like UNIDO to implement the Montreal Protocol and the subsequent Kigali Amendment requirements. This is leading to the transfer of advanced technologies related to the refrigerants’ recovery and reclamation to these countries.

At the inauguration of the refrigerant reclamation centre at the Escuela Politécnica del Litoral (ESPOL) in Ecuador.

The private sector also plays a key role in setting up the necessary infrastructure for the recovery and reclamation process. Only through a joint climate action from all–from multilateral agencies, national governments, financial institutions, private sector and the civil society, we can address the challenges of climate change.

Having a robust legislation in place and its implementation mechanism, along with the joint efforts of all stakeholders can play a crucial role in maintaining the efficiency of cooling systems, reduce the demand for new refrigerants and prevent the release of harmful substances into the atmosphere.

CONTACT US

Subscribe to our newsletter

Sign up to receive a quarterly email with updates and new content!

Disclaimer

The information presented in this newsletter does not necessarily reflect the views of UNIDO. Links to external websites are included solely to provide additional information and do not imply any official endorsement of the opinions, ideas, data, or products presented.

© 2023 UNIDO Montreal Protocol