Share this:

Welcome to the UNIDO Montreal Protocol Newsletter

For the coolest month of the year, we are happy to bring you some fresh insights on “why cooling matters”, with our latest newsletter edition.

In keeping with this year’s World Refrigeration Day theme, we would like to share some insights on cooling’s essential benefits, how cooling impacts daily life and how technology choices can shape the environmental well-being for future generations.

This last point is what drives the daily work of UNIDO’s Montreal Protocol Division. How our work, and cooling as a whole, relate to cross-cutting areas such as climate change, circular economy, gender and youth is therefore explored in our Ask UNIDO section.

The interview with the National Ozone Unit of Argentina features another key cross-cutting element of our work: skills development. Read about Argentina’s technician training and certification programme, for practical advice for Governments and educators on launching a successful certification scheme.

As inspiration for further action on sustainable cooling, don’t miss our feature article on the historic cooperation between China’s FECO and UNIDO’s Montreal Protocol Division. Learn about the achievements to date and the benefits for both industry and the environment. Finally, test your knowledge on sustainable cooling in our quiz section and get inspired by our latest events and social media posts.

Keep cool and happy reading!

Your UNIDO Montreal Protocol Division

ASK UNIDO

Regina Vellmer

INTERVIEW

Laura Berón

FEATURE ARTICLE

Dingding Shao

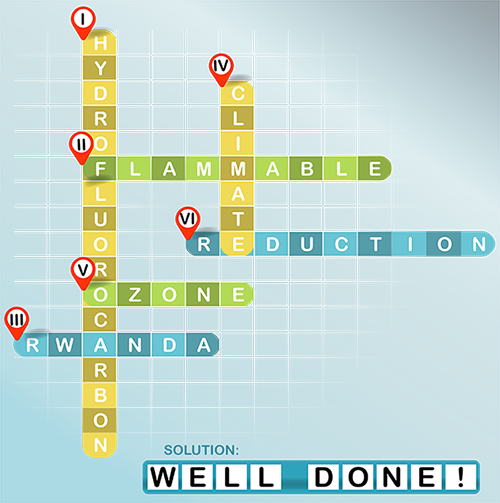

QUIZ - Did you know?

Test your knowledge!

In celebration of the World Refrigeration Day 2022, learn about some refrigeration facts and ideas to try at home for saving energy and reducing food waste.

Have "Eat Me First" box.

Add a ‘leftover veggies’ container to the freezer.

Keep it full

Fill your empty containers with water and put in the freezer.

Give it space.

Keep out the heat.

Vacuum/clean the coils

Move your fridge away from

the wall

Buy a thermometer and pop it

in the fridge

NOTICE BOARD

Spotlight

Read this post on how UNIDO contributes to SDG 4 on Quality Education in Guatemala by donating a R-290 split to the School of Mechanical Engineering of the University of San Carlos.

Social Media

Tune into a short video on the importance of energy efficient cooling systems, prepared by the National Ozone Unit of Turkey.

Events

Be inspired by regional cooperation on the Kigali Amendment, with this year’s first in-person workshop on UNIDO’s approach on the Kigali Implementation Plan (KIP) and the opportunities for Western Balkan countries.

ASK UNIDO

You Ask, We Answer!

Regina Vellmer, Project Management Consultant at UNIDO’s Montreal Protocol Division, elaborates on the

cross-cutting elements the Montreal Protocol addresses on achieving the SDGs.

(6 minutes reading time)

In 2015, with the adoption of the 2030 Agenda for Sustainable Development and its 17 Sustainable Development Goals (SDGs), the global community reaffirmed its commitment to sustainable development. The 2030 Agenda considers a number of thematic and cross-cutting issues that must be addressed in parallel in order to build an inclusive and sustainable future. Now the question is, how many of these cross-cutting elements are addressed under the Montreal Protocol, and how can such an environmental agreement help us achieve the SDGs?

Climate Action

Following the release of the latest IPCC report, the global community was alerted to the limited time remaining to mitigate the worst effects of climate change: in a nutshell, the time to act is now! UNIDO’s Montreal Protocol Division has been a global player in combating climate change issues since 1993. Our daily activities provide support to developing countries and economies in transition in planning, developing and implementing activities for compliance with the Montreal Protocol and the Kigali Amendment to the Montreal Protocol (KA). We are assisting countries to achieve their Nationally Determined Contributions (NDC) to reduce emissions of greenhouse gases (GHG) under the Paris Agreement. These interventions significantly contribute to the fight against climate change by phasing down hydrofluorocarbons (HFCs). HFCs are potent greenhouse gases, used notably in the refrigeration, mobile and stationary air-conditioning and foam sectors. While HFCs have a low- to-zero impact on ozone depletion, due to their high Global Warming Potential (GWP), they trap heat in the lower atmosphere, thereby contributing to global warming. The work of UNIDO’s Montreal Protocol Division (MPD) focuses on sustainable and transformative approaches to reducing further GHG emissions and only in 2021, 69.3M tons of CO2 emissions have been potentially avoided. If you are interested in reading more about the importance of the KA in supporting Climate Action, make sure to browse through issue 2 of this newsletter.

Circular Economy

Nature knows no waste: everything is broken down and reused in natural ecosystems. In contrast, human-made industries create massive amounts of waste, endangering the existence of life on this planet. The majority of global waste ends up being incinerated or piled up in landfills, rivers and finally in the ocean. Around the world, municipal solid waste contributes 11% of total methane emissions. A lot of that has to do with food waste, which releases 8% of global greenhouse emissions. Globally, one-third of all food produced ends up in the trash[1].

One of the approaches to fight the human waste problem and to achieve sustainable industrial development is circular economy (CE). UNIDO defines circular economy as an industrial economy that routes materials, parts and products back into use, repeatedly, to create more value and less waste. It is an alternative in which value is retained for as long as possible, products are designed to last, and the generation of waste is minimized. CE strategies cover the three pillars of sustainable development. From the perspective of economics, resource productivity increases through reduced production costs and improved competitiveness. A reduced environmental impact is achieved through fewer emissions of GHGs and other pollutants, safeguarding ecosystems and biodiversity. Finally, the well-being of people improves significantly through the creation of new jobs and better health conditions, from reduced pollution. In MPD, we support stakeholders in developing circular economy strategies and policies, applying these directly within industries. We work directly with companies to transform their linear production models of take, make, dispose, reduce, reuse, repair, redesign, remanufacture, recycle, and recover. Working predominantly with the foam sector, the refrigeration and air-conditioning (RAC) manufacturing sector and the RAC servicing sector, UNIDO has already supported more than 70 countries[2], with services including the following:

From CIRCULAR ECONOMY and the Montreal Protocol Division

Gender Equality

Gender inequality, coupled with the climate crisis, is one of the greatest challenges of our time. Both challenges are based on the existing systems of power, politics and economics. Industrial development can be inclusive and sustainable only if everyone is equally involved, both men and women. Women and girls continue to face difficulties in accessing education and job opportunities only because of their gender. Gender, as understood by UNIDO, refers to the different roles, opportunities and relationships between women and men that are socially constructed and learned through socialization processes. Beyond recognizing specific vulnerabilities resulting from differing gender roles, women are key agents of change, who, as economic actors, leaders[3] and consumers, play vitally important parts in every country’s drive towards a higher level of industrialization in their economies. The 2030 Agenda for Sustainable Development has placed a much-needed focus on sustainable industrialization and gender equality, highlighting the importance in industries and sectors where women have limited or no access to education or the job market. This applies especially for jobs in so-called STEM (science, technology, engineering, and math) field, as offered in the RAC industry. That is why at MPD, we assist governments to mainstream gender in sustainable development policies and interventions, as well as industries and institutions to deliver targeted actions to promote gender equality. This requires careful planning and dedicated training, to promote gender equality and women empowerment throughout the entire project cycle.

In the last two years, UNIDO’s MPD started to offer a training on Basic Concepts and Introduction to Gender Mainstreaming as a first step of awareness-raising and introduction into the topic and this important goal. This activity was awarded with a Gender Equality Mobilization (GEM) Award in 2021, ensuring that all genders can equally lead, participate in and benefit from industrial development, and in creating industries, economies and societies that are more equal. If you want to read more about its success in Mexico, have a look at Issue 4 of this newsletter, where we interviewed the National Ozone Unit about the two-day training. Without gender equality it will be very difficult to reach a sustainable and equal future and the world communities have to work together to make it a reachable goal in our agendas.

Youth

“The best hope to address the challenges confronting the contemporary world, including those to peace, impacts of climate change and growing inequalities, is with the new generations, we need to make sure that we are able to strongly invest in those new generations”- Secretary General, Antonio Guterres, on the role of youth addressing today’s challenges[4]. UNIDO’s MPD offers training and capacity building to young adults, to build opportunities for future and better employment. At the same time, we are encouraging our project partners in the RAC sector to particularly engage young adults in the development and implementation of sustainable development interventions.

Partnership

All of our achievements to date are owed to the strong commitment of governments, industries, specialized agencies and other stakeholders working together towards our common goals. UNIDO’s Montreal Protocol Division plays a leading role in fostering partnerships with the private and public sectors, donors, and specialized agencies to contribute towards the implementation of industrial development projects. We promote south-south and triangular cooperation, through the transfer of technology, knowledge exchange and capacity building, to harness the full potential of our interventions and scale-up the benefits of sustainable industrial development. The cooperation of GIZ, UNDP and UNIDO for the project Sustainable and climate-friendly Phase-out of Ozone Depleting Substances (SPODS) is an excellent example of successful partnerships working towards a common goal. Here the objective was to provide assistance to selected Latin American and Caribbean (LAC) countries, to advance their ODS phase-out and HFC mitigation at the same time. GIZ, UNIDO and UNDP each supported different stakeholders, based on their individual expertise, thereby engaging a wider platform of partners in each of the target countries. National Ozone Units worked in cooperation with the implementing agencies on executing activities, particularly coordinating with stakeholders. The success of this partnership can be best appreciated from the engagement of the local partners and at a regional level, momentum is building and propelling LAC countries forwards. If you would like to learn more about the implementation of this global partnership for sustainable development, dive into our latest Montreal Protocol publication.

From these partnerships, we have learned that “the whole is greater than the sum of its parts”. This can also be applied to our work under the Montreal Protocol, where we can say that each of our projects have contributed to the recovery of the Earth’s ozone layer. Moreover, though our work is driven by our determination to protect the ozone layer and safeguard our planet, our actions contribute to other development objectives. By adapting and responding to the needs of our global society, we have found ways to make our interventions more cost-effective and far-reaching, embracing a number of cross-cutting elements. Together, we can “save the planet” while also driving action on the 2030 Agenda and making a lasting contribution to sustainable development.

[1] https://www.globalcitizen.org/en/content/global-waste-facts-plastic-fashion-food/

[2] To see concrete examples go to the publication CIRCULAR ECONOMY and the Montreal Protocol Division

INTERVIEW

Interview with Laura Berón

Laura Berón, Coordinator of the National Ozone Unit, and Graciela Garau, Technical Consultant at the National

Ozone Unit of Argentina, on the technician training and certification programme in Argentina.

(4 minutes reading time)

What is the overarching goal of the technician training and certification programme in Argentina?

One of the main objectives under the HCFC phase-out management plan (HPMP) for Argentina was the reduction of HCFC consumption in the refrigeration and air conditioning (RAC) servicing sector. This was achieved by introducing alternatives to HCFC with a lower ozone-depleting potential (ODP) and wherever possible a lower global-warming potential (GWP).

While better for the environment, some of the low GWP refrigerants are also highly flammable, so handling them requires technical training and specialized skills.

The National Ozone Unit of Argentina, OPROZ, set as a priority to promote the training of RAC service technicians on the safe handling of these refrigerants, with a view to a subsequent certification. The ultimate goal was to help experienced service technicians safely manage flammable refrigerants when planning, installing, servicing and repairing RAC appliances.

Could you describe the process for initiating the training and certification programme in Argentina and how the National Ozone Unit addressed any major challenges?

The first step in the process was to engage qualified trainers. OPROZ selected eighteen national RAC experts for this programme,

In 2019, as part of the bilateral cooperation between the Italian Ministry for the Environment, Land and Sea and the Argentinian Government Secretariat of Environment and Sustainable Development a delegation of 20 professors (2 from the National Technological University, certification body) and representatives from Argentinian Government gathered in Casale Monferrato, Italy, to attend a train-the-trainers course on flammable refrigerants. The selected trainers were assessed according to the REAL Alternatives 4 LIFE blended learning programme for safe handling of flammable refrigerants; after a fully positive outcome, all participants were successfully certified.

Specific equipment and tools were then procured by UNIDO and delivered to each of the trainers by OPROZ in January and February 2020. The training program was launched in March 2020 with an inception meeting and a training session on the use of a specially designed mini-benches to study the refrigeration circuit and simulate different possible faults, in order to reinforce basic refrigeration competences.

OPROZ developed a training manual and course materials for the training programme. UNIDO concluded contracts with each of the trainers for the delivery of the courses.

OPROZ also worked closely with the National Technological University (UTN) – the national certification body – to develop the methodology and materials for the theoretical and practical examination on the Safe Handling of Flammable Refrigerants.

Then came the COVID-19 pandemic and very strict restrictions on movement enforced by the Government of Argentina in 2020 and 2021, so the programme faced significant delays.

Once the restrictions were finally lifted, the training programme was relaunched and is advancing well. To date, six (6) training courses have been delivered in San Juan (2), Salta (2), San Miguel de Tucuman (1) and Termas de Río Hondo (1), with a total of 104 technicians trained. Certification exams have taken place in San Juan, Tucuman and Salta and, so far, fifty-four (54) technicians have been certified.

Approximately fifteen (15) additional courses are planned to take place between now and August 2022.

What are the next steps and what is your vision for the future?

In order to incentivize participation in the certification scheme, the first 1,000 certified technicians will receive specific tools for working with flammable refrigerants. UNIDO has initiated the procurement process for the purchase of this equipment and OPROZ oversees the equipment delivery.

What are some of the lessons learned you could share with other National Ozone Units embarking on this process?

The refrigeration service sector in Argentina is rather informal, there are very few national institutes of higher learning for this profession, so it was decided that the courses should also focus on the theoretical aspects related to refrigeration with the aim of improving the overall knowledge of technicians in this profession.

So, in addition to the safety issues related to flammable refrigerants, subjects such as basic thermodynamics, principles of the refrigeration cycle, Mollier diagram, pressure/temperature charts, classification of blends and their different behaviour, basic concepts related to the design and service of refrigeration systems with flammable refrigerants, etc. were included in the courses’ curricula.

With that in mind, it was very important to assemble a team of trainer’s with not only solid theoretical knowledge but also significant practical experience, who could address technicians in their language, what we call “workshop jargon”, to facilitate fruitful discussions with them.

Regarding the certification exams, these were originally designed solely on the manual’s contents, but, once the courses began, and with them the interaction with the technicians, we realized that a more practical approach would be necessary, so, we changed a lot of questions to reflect this.

Notwithstanding, at the end of each exam, questions are analysed in order to see if other changes would also be necessary, such as, for instance, the language used.

Exams also have certain questions related to safety issues that are considered “essential”, meaning that in order to pass they must be correctly answered, no matter how many others are also correct.

One final important issue to consider was that technicians are not students and are not used to exams. So, an evaluation was taken after each course to prepare them for the real exam and to see if a subject was not properly understood and needed extra considerations. The results of these evaluations were discussed with each of the participants, so they could know which subjects would need further study. For that, trainers organized extra consultations and review classes. With this personalised approach, we are sure that we are building qualified professionals, who will have a lasting understanding of these topics (beyond the exam) and who will make valuable contributions to the RAC servicing sector of Argentina.

FEATURE ARTICLE

UNIDO and FECO working hand-in-hand to combat climate change

Dingding Shao, International Consultant from FECO, on the successful collaboration of UNIDO and FECO to combat climate change

(3 minutes reading time)

Background

Last year was the 30th anniversary of the Chinese government’s accession to the Montreal Protocol. Over these 30 years, China has also worked hard to contribute to the UN Millennium Development Goals and Sustainable Development Goals, advance China’s development plans and apply Chinese wisdom for global efforts in strengthening international cooperation. China has established new compliance mechanisms, implemented innovative industry phase-out plans, and promoted technological innovation, with a cumulative phase-out of about 500,000 tons of ozone-depleting substances (ODS).

The Foreign Environmental Cooperation Center (FECO), under the Ministry of Ecology and Environment, is an important platform for China’s international cooperation and exchanges in ecological and environmental protection. FECO was established by integrating the Foreign Economic Cooperation Office of the Ministry of Environmental Protection (Technology Center for Environmental Convention Implementation, MEP), and the China-ASEAN Environmental Cooperation Center (China Center for Shanghai Cooperation Organization Environmental Cooperation, Lancang-Mekong Environmental Cooperation Center). This gives FECO its unique character, as it integrates the combined functions of the four above-mentioned organizations.

Contribution to industry and environment

In the field of multilateral cooperation, FECO has a long-standing and extensive cooperation with UNIDO in developing, implementing and managing projects on international environmental agreements. These include projects to support the implementation of the Montreal Protocol on Substances that Deplete the Ozone Layer, the Stockholm Convention on Persistent Organic Pollutants, and the Minamata Convention on Mercury, with project activities including technical assistance, policy research, capacity building and technical training for national experts. Under the Montreal Protocol, since 1992, China and UNIDO have jointly developed and implemented over 50 individual ODS phase-out projects, 7 umbrella programs and 10 sectoral plans, involving domestic refrigeration, air conditioning, foam, pharmaceutical, agriculture, food, tobacco and other sectors, with a total project grant funding of approximately 480 million USD.

UNIDO has actively helped China to introduce and promote environmentally friendly and low-carbon alternative technologies. During the CFCs phase-out process in the 1990s, with the support of UNIDO, China’s refrigerator manufacturing industry adopted hydrocarbon foaming agents and refrigerant technology, and then successfully promoted this technology globally. The successful application of ozone layer and climate-friendly natural refrigerants such as propane (R290), carbon dioxide and ammonia developed by Chinese enterprises in domestic air conditioning, heat pump, refrigeration and freezing, as well as the widespread promotion of carbon dioxide as an environmentally friendly blowing agent in the XPS foam industry, have played an important role in cutting ODS, reducing greenhouse gases, and the rational use of energy in China. Statistics show that from 2006 to 2016, China’s energy consumption per unit of GDP dropped by 37.3%, with a cumulative energy saving of 1.8 billion tons of standard coal, equivalent to a reduction of nearly 4 billion tons of carbon dioxide. Taking the air conditioning industry as an example, the overall energy efficiency level of domestic air conditioners in China has increased by 20% on average over the past 10 years.

The workshop after retrofit in China

Flagship projects and key achievements

Since 2008, FECO and UNIDO have cooperated in the development and implementation of the HCFCs phase-out management plan (HPMP) for the room air conditioner sector and XPS foam sector in China, with a total project funding of about USD 225 million, divided into the first phase (2010-2015) and the second phase an (2016-2026). Under the HPMP, with the guidance and technical support of UNIDO, China’s room air conditioner industry began introducing ozone layer and climate-friendly R290 as the main alternative refrigerant. The room air conditioner sector has now completed the conversion of 29 production lines, with the output of R290 air conditioners exceeding 260,000 units in 2020. The XPS foam sector has adopted carbon dioxide and other environmentally friendly foaming agents to phase out HCFCs, and 25 enterprises have signed retrofit contracts for the conversion of their production processes. Since 2018, UNIDO and FECO have been actively engaged in the implementation of the second phase of the HPMP, including working on alternative technology development, promotion and application, and engaging in conversion contracts with 19 enterprises, all of which have adopted low-carbon and environmentally friendly alternative technologies, phasing out about 6,518 tons of HCFCs.

International Workshop

Project activities

Future outlook

At present, China has announced its carbon emission peak target and carbon neutrality vision, and the policy measures to control HFCs to implement the Kigali Amendment have come into effect nationwide on September 15, 2021, which also provides opportunities for FECO and UNIDO to further cooperate in this field. It is believed that the joint efforts of both FECO and UNIDO will make new contributions to protect the ozone layer, tackle climate change and promote sustainable industrial development.

CONTACT US

Subscribe to our newsletter

Sign up to receive a quarterly email with updates and new content!

Disclaimer

The information presented in this newsletter does not necessarily reflect the views of UNIDO. Links to external websites are included solely to provide additional information and do not imply any official endorsement of the opinions, ideas, data, or products presented.

© 2022 UNIDO Montreal Protocol